Multimode special optical fibers

Multimode special optical fibers

Laser beam transmission with applications in manufacturing, medicine, spectroscopy, sensor technology and high-power laser transmission

Graded-index and step-index multimode fibers are used for data and power transmission. Undoped Fused Silica as a core material offers low attenuation and permits higher-power transmissions, e.g. from high-power lasers. Doped silica is used if a high numerical aperture is required for optimal launching of light into the fibers or to implement special fiber profiles. The size and shape (geometry) of the fiber core can be adjusted to match application requirements. With a suitable coating material and an optional buffer layer, the fibers can be protected from a wide range of environmental factors. All fibers can be adjusted, optimized, and assembled specifically for the customer’s individual application scenario along the entire value chain – from the initial manufacture of the Fused Silica starting material through to the final assembly.

We offer a broad portfolio of optical fibers that enables us to cover any wavelength range from ultraviolet through to near-infrared. You can select your fiber geometry from core sizes of 10 µm to 2.7 mm, and a wide range of circular and non-circular core/cladding fiber designs. Alongside multimode special optical fibers, we also make capillaries and tapers.

- Superior flexibility and product diversity due to strong vertical integration – from the starting material to the finished product

- Customer-specific fiber designs and geometries

Range of products and services

Product portfolio

- Transmission range from ultraviolet (UV) to near-infrared (NIR)

- Core diameters from 10 µm to 2.7 mm

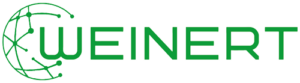

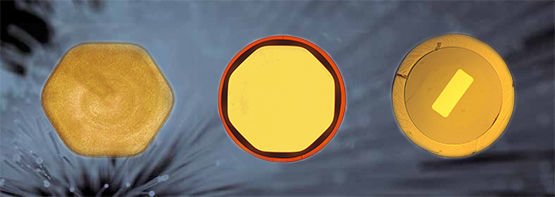

- Circular and non-circular core/cladding fiber designs (NCS – non-circular shape)

- Hexagonal core/cladding

- Octagonal core/circular cladding

- Square core/circular cladding

- Rectangular core/circular cladding

- Step-index, graded-index or customer-specific refractive index profiles

- Numerical aperture from 0.1 to 0.40 (quartz/quartz) or 0.37 to 0.49 for HPCS and PCS fibers

- Wide range of coatings, including acrylate, low-index acrylate, high-temperature acrylate, silicone, polyimide, to match application temperatures of up to 385 °C

- Optional cladding with polyamide or ETFE buffer materials to protect fibers from environmental influences

- Customer-specific assembly for your application scenario

Product properties

- Broad temperature spectrum

- Optimized for use in UV

- Optimized for use in IR

- High mechanical strength and stability

- Resistance to chemicals and other media

- Laser fibers with high damage threshold

- Multilevel fibers for laser applications

Ordering options

- Wavelength

- Fiber and core geometries (circular/non-circular, multilevel fiber design)

- Core diameter

- Cladding diameter

- Numerical aperture

- Refractive index profile: step- or graded-index profile, user-defined refractive index design

- Buffer: polyamide or ETFE

- Coating material

- Available as assembly

- Can be ordered as fiber bundle

- Autoclavable

Fields of use

- Spectroscopy

- Sensor technology

- High-power laser transmission

- Laser surgery

- Environmental analysis

- Quality control

- FTIR

Applications

Other Products

Further information

Thanks to their versatility and advantages, multimode special fibers enable the development of ambitious, innovative technologies in all fields of data and power transmission, while offering maximum performance and tolerance versus mechanical loads, radioactivity and UV radiation. As a global fiber supplier with long experience in the development and manufacture of multimode special fibers, we offer a broad-based portfolio of fibers, assembly options and optical special components.

All of our special fiber products can be adjusted to match customer-specific requirements. Our manufacturing capacities enable us to achieve demand-based production output control from prototypes through to the certified manufacture of large fiber orders. We can offer you support for the development of innovative technologies, the achievement of ambitious growth targets, individual product diversification strategies, and compliance with scheduling requirements.

Contact

Please contact us for further information. We look forward to your inquiry.

Europe, Africa, and Asia (excl. China)

Phone +49 36764-81-100

Email sales-europe@weinert-industries.com

China

Phone +86

519-8988-7783

Email sales-china@weinert-industries.com

North and South America

Phone +1

757-258-4805

Email sales-americas@weinert-industries.com